Horizontal lathes

Highlight-Machine :

DMG Mori – CTX gamma 2000 TC

Powerful & process-optimised. Our CTX gamma 2000 TC machines enable a 6-side complete machining for the flexible manufacture of highly complex components. In combination with CNC automatisation, we manufacture your components in any batch size.

Turning contours in a variety of diameter ranges

A total portfolio of 17 horizontal and vertical lathes enables us to cover a large bandwidth of machining dimensions and component geometries. From diameter 10 mm to 5,200 mm we offer our services for manufacturing of rotationally-symmetric geometries, flexibly and efficiently. Moreover, several of our lathes have integrated boring and milling units that allow 6-sided complete machining without changing machines. In conjunction with our milling centers and boring mills we are also able to manufacture rotationally-symmetric components with highly-complex prismatic elements. Our grinding technology reliably fulfills increased requirements imposed on dimensional and surface tolerances. Thanks to exclusive use of CNC technology, as well as our in-house programming with preliminary simulations, we manufacture precisely, economically, and with process reliability.

Partial or complete machining as a service

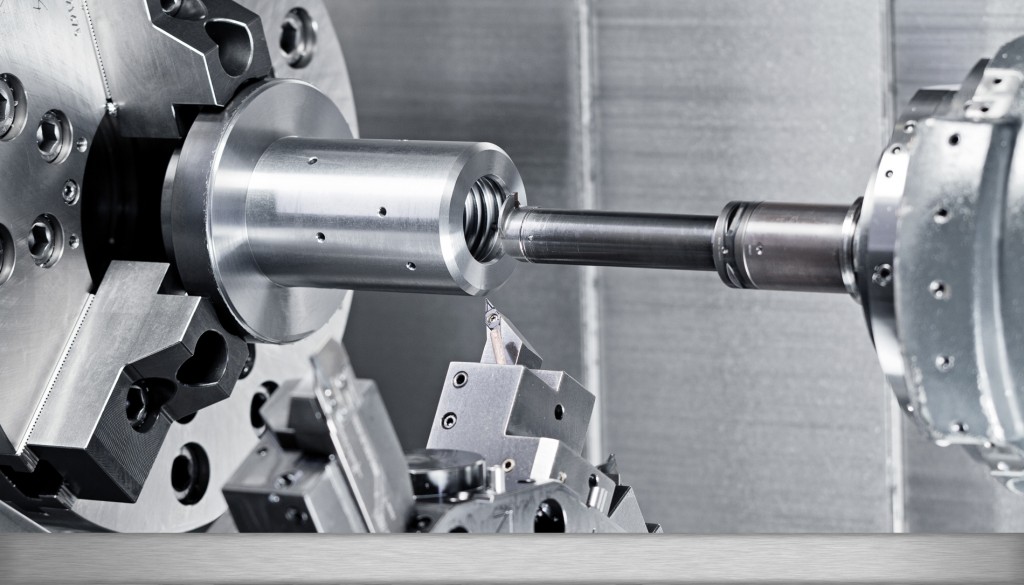

Horizontal Turning Technology

- State-of-the-art CNC turning and milling centers

- Synchronously operating main spindle and counter spindle

- Controlled 5-axis boring and milling unit

- Extensive tool and jig assortment

- Tolerance compliance to 0.01 mm

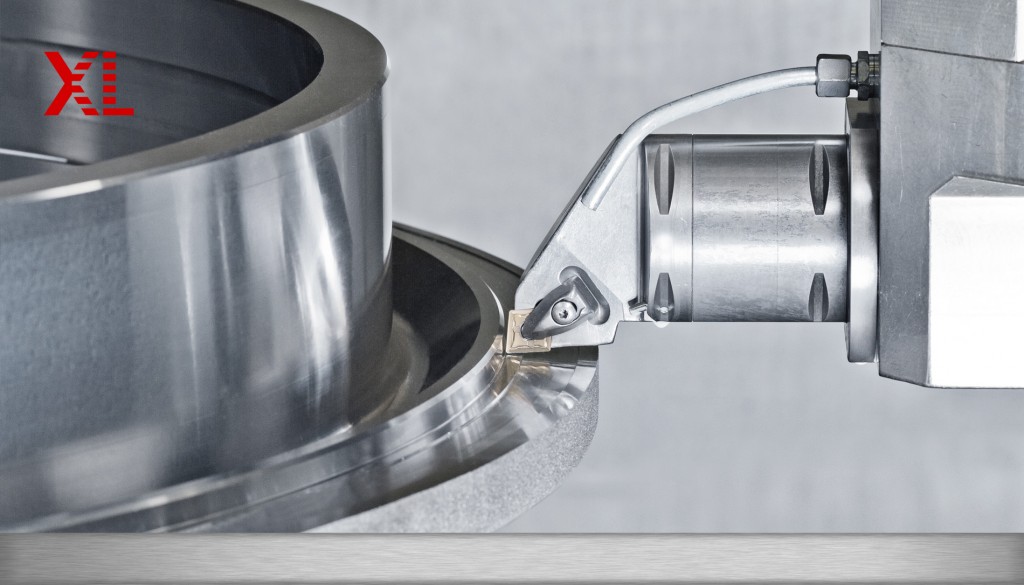

Vertical Turning Technology

- Turning to 5,200 mm (face plate 4,000 mm)

- Maximum component weight 25 t

- Controlled 3-axis boring and milling unit

- Machining of half-components

- Tolerance compliance to 0.02 mm

More information concerning our machine equipment: